Description

TOOLOX 33 is a quenched and tempered tool steel designed to have low residual stresses and extremely good machinability.

Applications include:

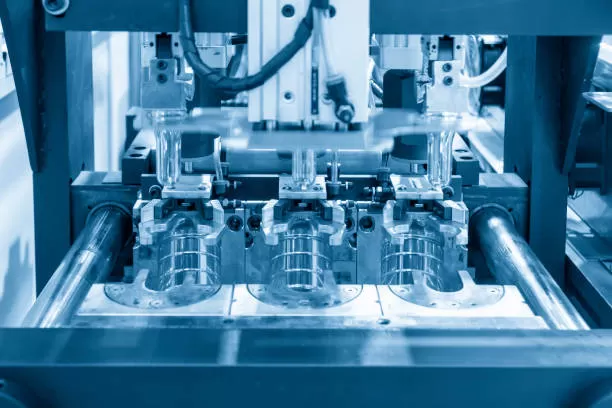

Plastic Molds

Rubber molds

Bending tools

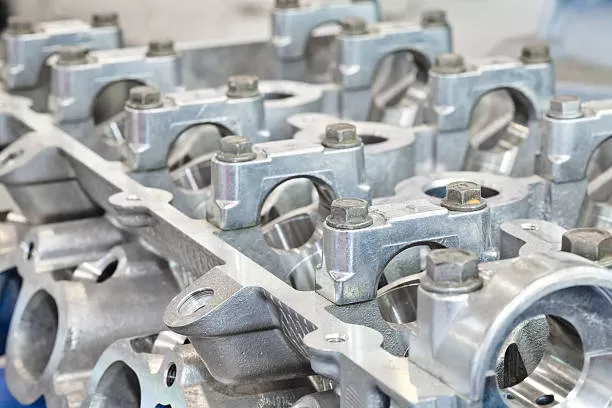

Machine components

Unique Characteristics

- Especially suited for plastic molds and rubber molds, having excellent polishing and photoetching ability.

- Supplied in plate thickness 1/2” – 5 1/8”.

- Hardness 30-35 HRC.

Product Brochure

Specifications

| Hardness

(Guaranteed values) |

HBW 280-330 (Approx. 30-35 HRC) |

|

| Impact properties

(Guaranteed values) |

Testing temperature °C 20-400°C | Impact energy, Charpy-V, longitudinal direction; min. ft. lbs. < 74-133 |

| Tensile Properties

(Calculated values) |

Tensile strength approx. 130 – 142,000 PSI | |

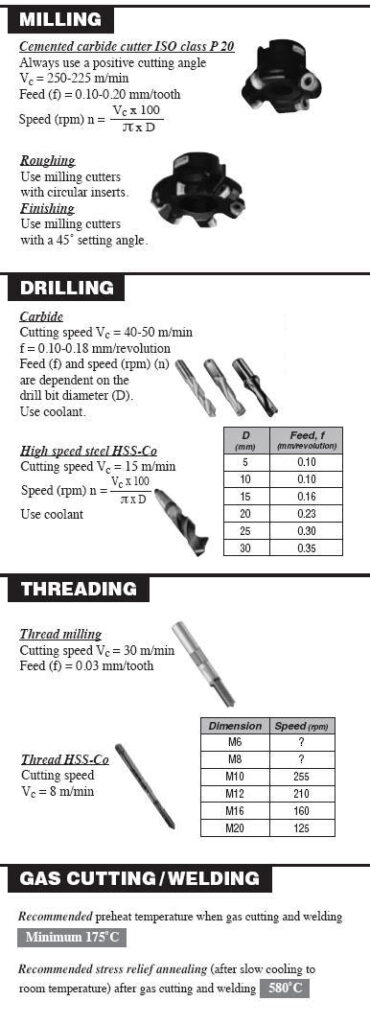

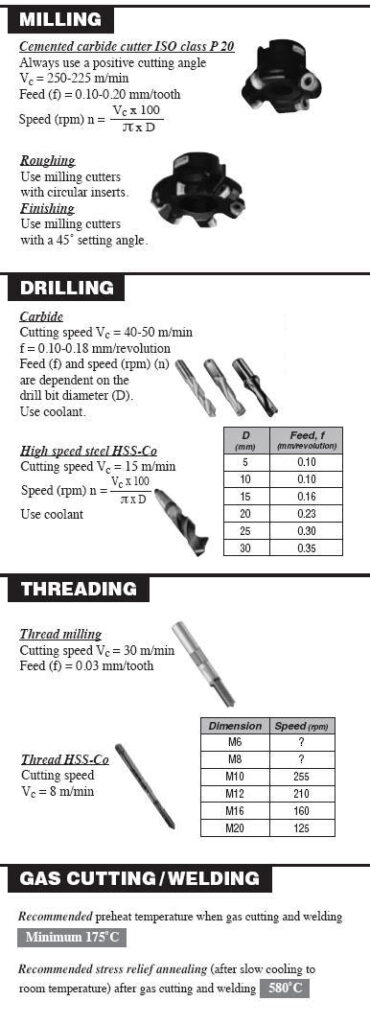

| Milling

(Calculated values) |

At cutting speed of 300 m/mm, feed 0.15 mm, 10 min. effective cutting time using a Sandvik Coromil 200 and inserts GC 1025, we guarantee max 0.3 mm edge wear. | |

| Ultrasonic insp.

(Guaranteed values) |

Discontinuities giving echoes at least equivalent in amplitude to flat bottom hole 1.5 mm shall be reported according to SSAB Standard V6. | |

| Etching properties

(Guaranteed values) |

TOOLOX 33 fulfills the demands according to NADCA 207-97. | |

| Dimensions

(Preliminary) |

TOOLOX 33 is supplied in plate thickness 3/4” – 5 1/8”. | |

| Delivery condition | Quenched and tempered at min. 590°C | |

| Heat treatment | TOOLOX 33 is not intended for further heat treatment If TOOLOX 33 is subjected to any heat treatment above 590°C, after delivery from SSAB Oxelösund AB, no guarantees concerning the properties of the matrial will be given. | |

| Testing | Testing in accordance with EN 10 137-1, 10 137-2 and EN ISO 6506-1. Hardness measured on a milled surface, 0,5-2 mm below surface. | |

| Tolerances | According to EN 10 029

• Thickness tolerances to Class C. |

|

| Surface finish | According to EN 10 163-2

• Surface requirements to Class B. |

|

Usages

TOOLOX 33 is a new quenched and tempered steel, designed to have low residual stresses. It is characterized by its extremely good machinability, in combination with a hardness of 30 HRC. The steel is especially suited for plastic moulds, having excellent polishing and photoetching ability. Other applications are for example rubber moulds, bending tools, recipient sleeves, etc.

Technical Information (Typical Values)

Machining

Record – Shoulder Milling

Record – Shoulder Milling

| Hardness

(Guaranteed values) |

HBW 280-330 (Approx. 30-35 HRC) |

|

| Impact properties

(Guaranteed values) |

Testing temperature °C 20-400°C | Impact energy, Charpy-V, longitudinal direction; min. ft. lbs. < 74-133 |

| Tensile Properties

(Calculated values) |

Tensile strength approx. 130 – 142,000 PSI | |

| Milling

(Calculated values) |

At cutting speed of 300 m/mm, feed 0.15 mm, 10 min. effective cutting time using a Sandvik Coromil 200 and inserts GC 1025, we guarantee max 0.3 mm edge wear. | |

| Ultrasonic insp.

(Guaranteed values) |

Discontinuities giving echoes at least equivalent in amplitude to flat bottom hole 1.5 mm shall be reported according to SSAB Standard V6. | |

| Etching properties

(Guaranteed values) |

TOOLOX 33 fulfills the demands according to NADCA 207-97. | |

| Dimensions

(Preliminary) |

TOOLOX 33 is supplied in plate thickness 3/4” – 5 1/8”. | |

| Delivery condition | Quenched and tempered at min. 590°C | |

| Heat treatment | TOOLOX 33 is not intended for further heat treatment If TOOLOX 33 is subjected to any heat treatment above 590°C, after delivery from SSAB Oxelösund AB, no guarantees concerning the properties of the matrial will be given. | |

| Testing | Testing in accordance with EN 10 137-1, 10 137-2 and EN ISO 6506-1. Hardness measured on a milled surface, 0,5-2 mm below surface. | |

| Tolerances | According to EN 10 029

• Thickness tolerances to Class C. |

|

| Surface finish | According to EN 10 163-2

• Surface requirements to Class B. |

|

TOOLOX 33 is a new quenched and tempered steel, designed to have low residual stresses. It is characterized by its extremely good machinability, in combination with a hardness of 30 HRC. The steel is especially suited for plastic moulds, having excellent polishing and photoetching ability. Other applications are for example rubber moulds, bending tools, recipient sleeves, etc.

Technical Information (Typical Values)

Record – Shoulder Milling

Record – Shoulder Milling