Description

DCMX is a matrix-type cold work tool steel: only fine carbides are distributed in matrix due to optimum alloy design and production process.

DCMX shows high performance in service and ease in mold making as well.

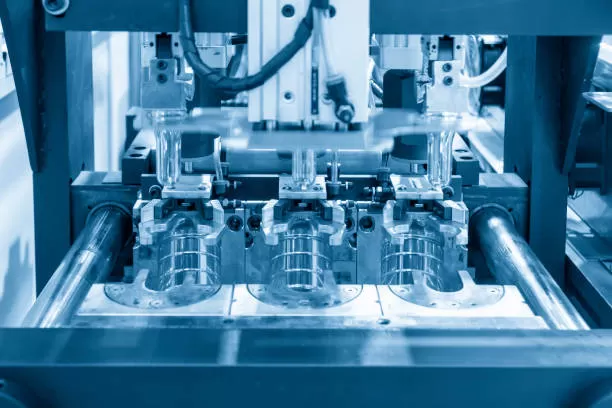

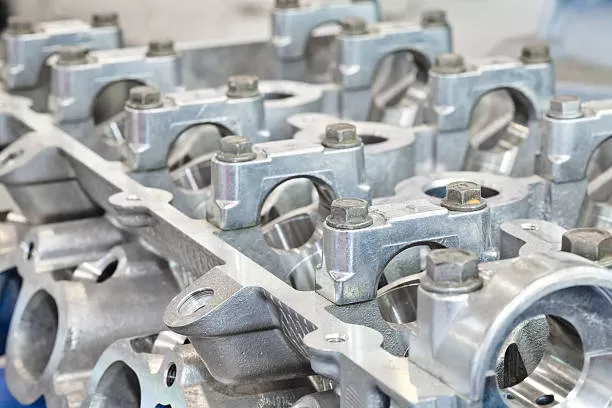

Applications include:

Punches

Dies

Working Tools for Cold Pressing and Cold Forging

Cold Stamping Dies for High Strength Steels

Insert Blocks for Composite Stamping Dies

Blanking Punches and Trimming Edges

Unique Characteristics

- High hardness such as 62 HRC is available by high temperature tempering with good dimensional stability, resulting in high wear resistance

- High toughness helps to prevent cracking and chipping.

- Isotropic dimensional change works easy geometry control in heat treating.

- Machinability is improved by free machining additives and finely dispersed carbides.

Product Brochure

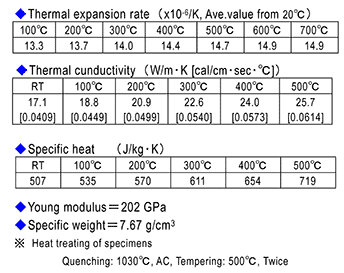

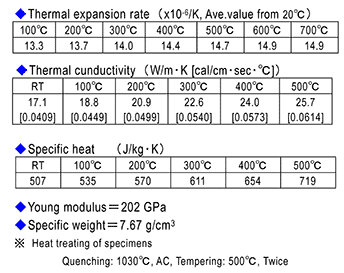

Physical Properties

Die Performance

- High hardness such as 62 HRC is available by high temperature tempering with good dimensional stability, resulting in high wear resistance.

- High toughness helps to prevent cracking and chipping.

Ease in Die Making

- Isotropic dimensional change works easy geometry control in heat treating.

- Machinability is improved by free machining additives and finely dispersed carbides.

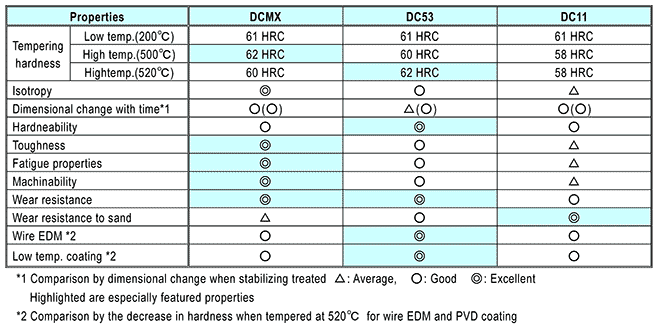

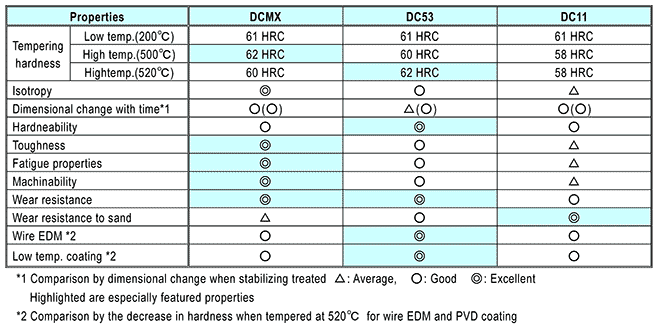

Physical Properties  Comparison of properties among Daido cold work die steels:

Comparison of properties among Daido cold work die steels:

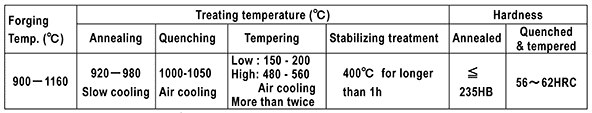

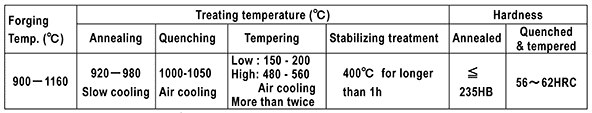

Heat Treatment

Heat Treatment

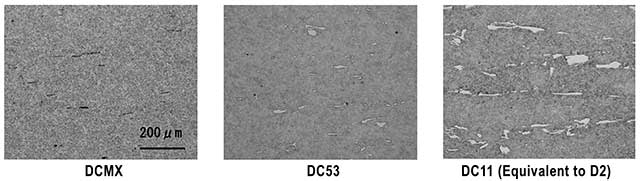

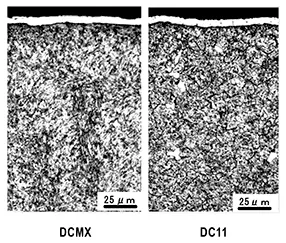

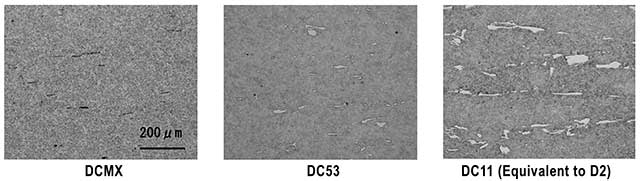

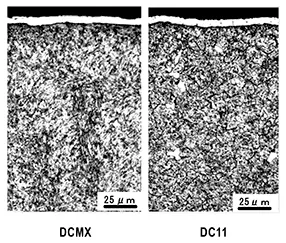

Optical Micrographs (Annealed)

DCMX shows fine microstructure almost free from coarse carbides

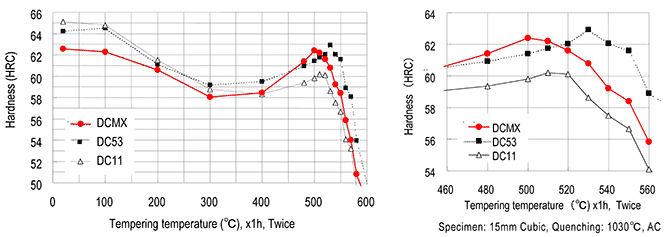

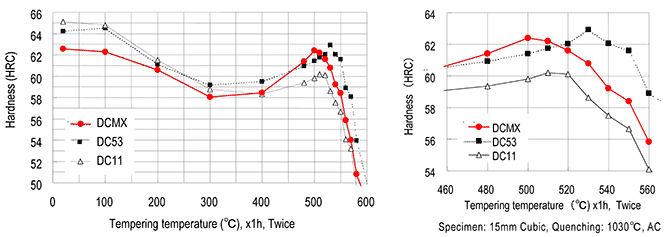

Tempering Hardness

Dimensional Stability

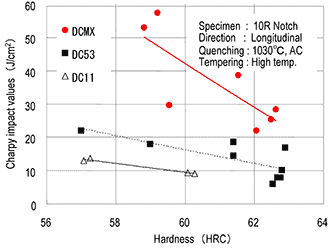

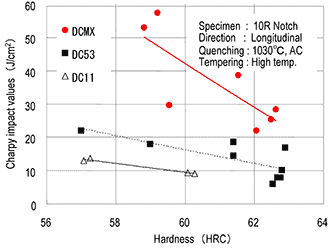

Toughness

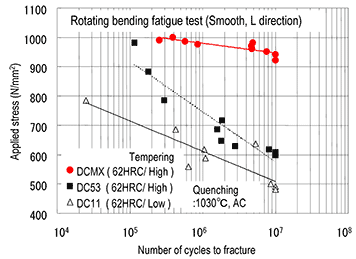

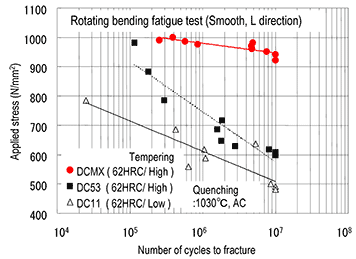

Fatigue Properties

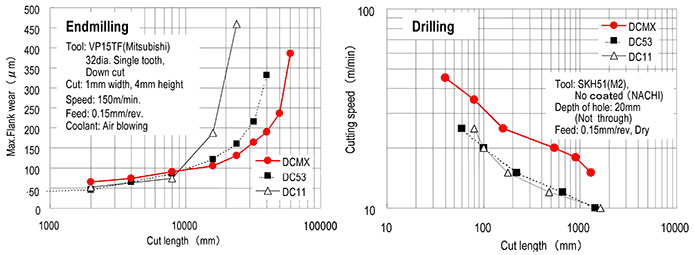

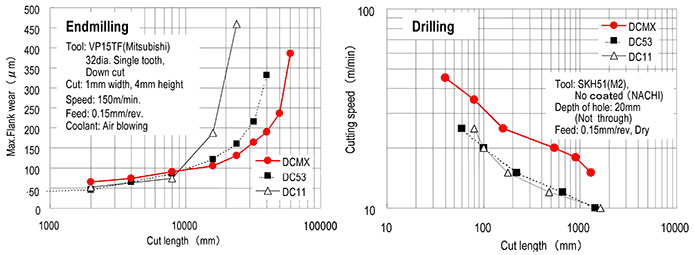

Machinability (Annealed)

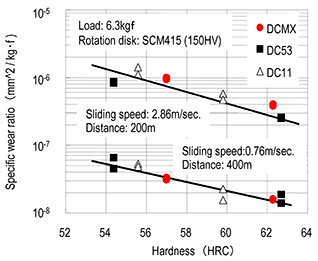

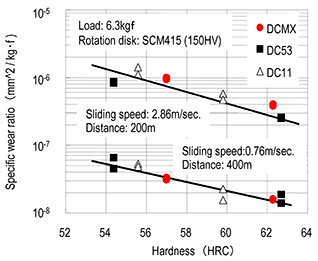

Wear Resistance (Ohkoshi-test)

TD Coating

TD coating: By courtesy of DOWA Thermo Engineering.

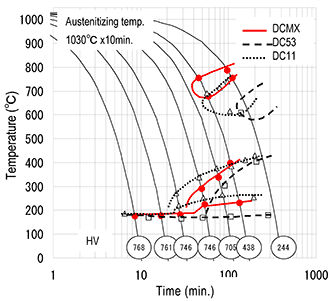

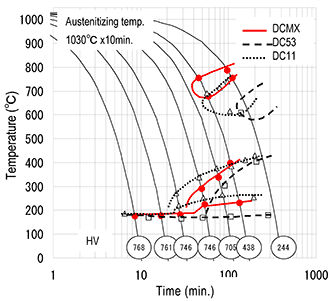

CCT Diagrams

Recommended Reading

Die Performance

- High hardness such as 62 HRC is available by high temperature tempering with good dimensional stability, resulting in high wear resistance.

- High toughness helps to prevent cracking and chipping.

Ease in Die Making

- Isotropic dimensional change works easy geometry control in heat treating.

- Machinability is improved by free machining additives and finely dispersed carbides.

Physical Properties  Comparison of properties among Daido cold work die steels:

Comparison of properties among Daido cold work die steels:

Heat Treatment

Optical Micrographs (Annealed)

DCMX shows fine microstructure almost free from coarse carbides

Tempering Hardness

Dimensional Stability

Toughness

Fatigue Properties

Machinability (Annealed)

Wear Resistance (Ohkoshi-test)

TD Coating

TD coating: By courtesy of DOWA Thermo Engineering.

CCT Diagrams