Description

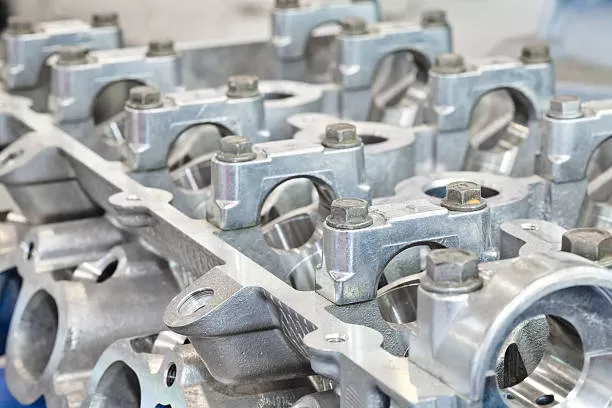

Diameters: Stocked in the pre-hardened condition (30-34 HRC) can be heat treated to 50-53 HRC

Plates: Stocked in the annealed condition. Can be heat treated to 50-53 HRC.

Applications include:

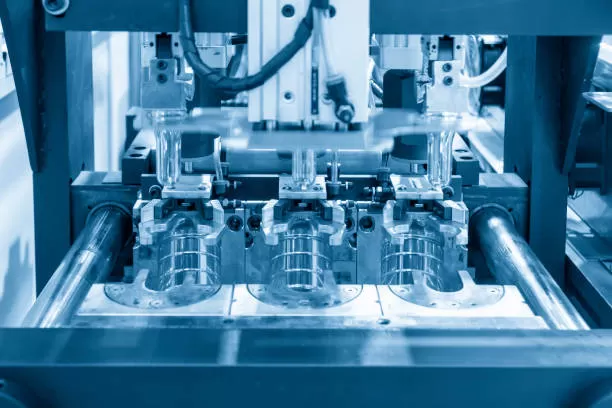

Ultra mirror finish plastic molds

Lens

Ultra-hard, Corrosion-resistance plastic molds

Medical Instruments, Cosmetic container, Food container

Resin PMMA, PC, PP, PS, PVC, PE, PF,

Flame resisting compound added resin

Unique Characteristics

- Excellent corrosion resistance

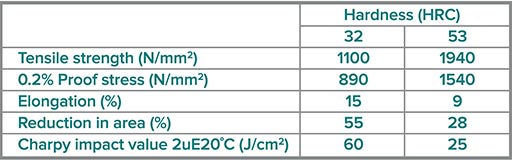

- High hardness: maximum 53 HRC is obtained

- Superb mirror-finish surface

- Minimal distortion, less than 0.03% after heat treatment

- Excellent internal matrix by ESR

- Uniform texture surface by photo etching and electrical discharge machining

Product Brochure

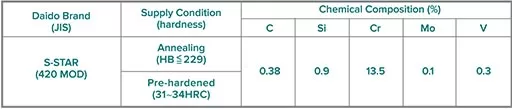

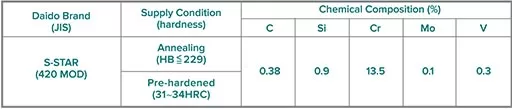

Chemical Composition

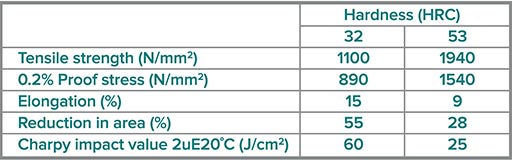

Mechanical Properties

Mechanical Properties

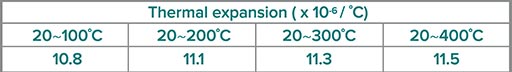

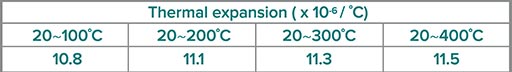

Thermal Expansion Coefficient

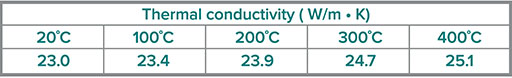

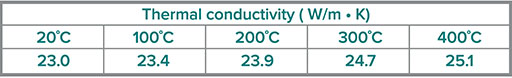

Thermal Conductivity

Longitudinal Elastic Modulus

Density

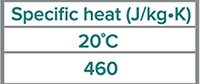

Specific Heaty

Physical Properties

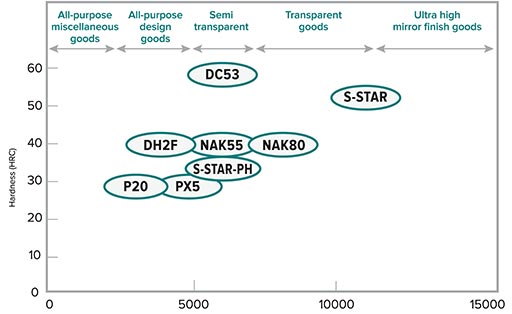

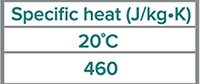

Mirror Grade Finish

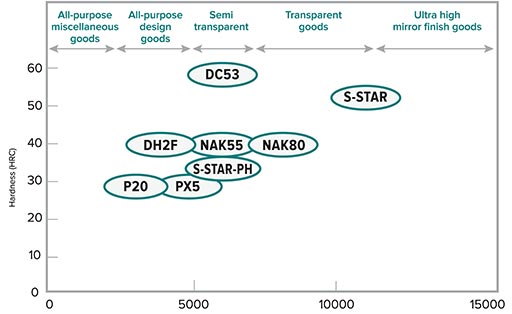

Heat Treatment

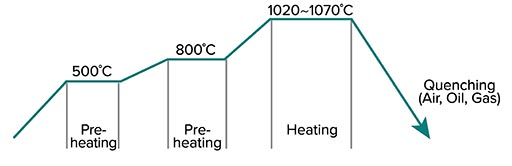

Hardened-Tempered Hardness Maximum hardness of 53HRC is obtained.  Quenching

Quenching  Tempering Double tempering is recommended for both low and high temperature tempering.

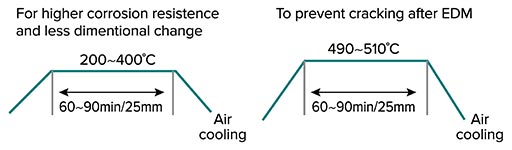

Tempering Double tempering is recommended for both low and high temperature tempering.  Notes:

Notes:

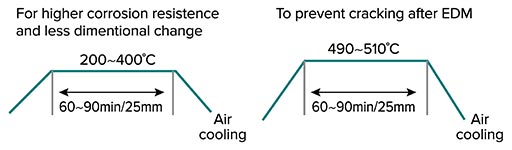

- For higher corrosion resistance, tempering should be carried out at temperatures of 400°C or lower.

- To prevent cracking in EDM, tempering is recommended at 490 to 510°C

- When aging dimensional stability is deemed important, carry out low-temperature tempering at 200 to 400°C or sub-zero processing.

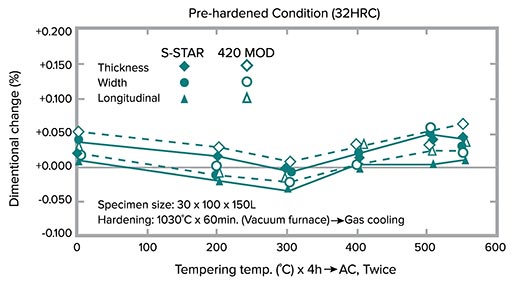

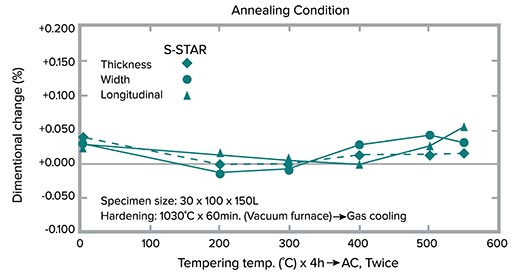

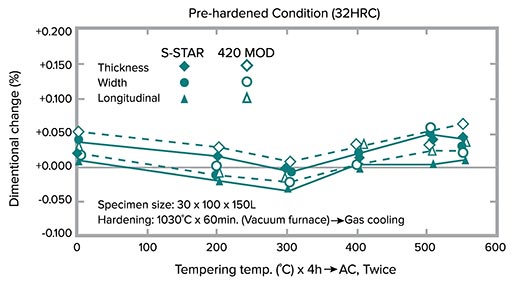

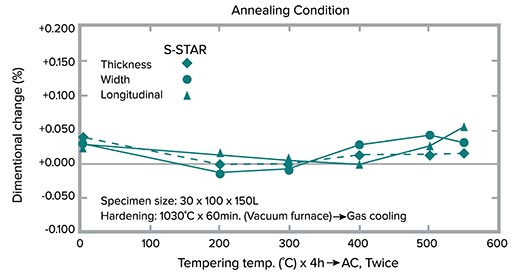

Dimensional Change Dimensional change is the smallest by tempering about 300°C

Welding Guidelines

Build-up Welding Procedures

Mechanical Properties

Thermal Expansion Coefficient

Thermal Conductivity

Longitudinal Elastic Modulus

Density

Specific Heaty

Mirror Grade Finish

Heat Treatment

Hardened-Tempered Hardness Maximum hardness of 53HRC is obtained.  Quenching

Quenching  Tempering Double tempering is recommended for both low and high temperature tempering.

Tempering Double tempering is recommended for both low and high temperature tempering.  Notes:

Notes:

- For higher corrosion resistance, tempering should be carried out at temperatures of 400°C or lower.

- To prevent cracking in EDM, tempering is recommended at 490 to 510°C

- When aging dimensional stability is deemed important, carry out low-temperature tempering at 200 to 400°C or sub-zero processing.

Dimensional Change Dimensional change is the smallest by tempering about 300°C

Build-up Welding Procedures