Description

TOOLOX 44 is a new quenched and tempered tool steel designed to have high impact and low residual stresses and therefore good dimensional stability.

Applications include:

Machine Components

Wear Components

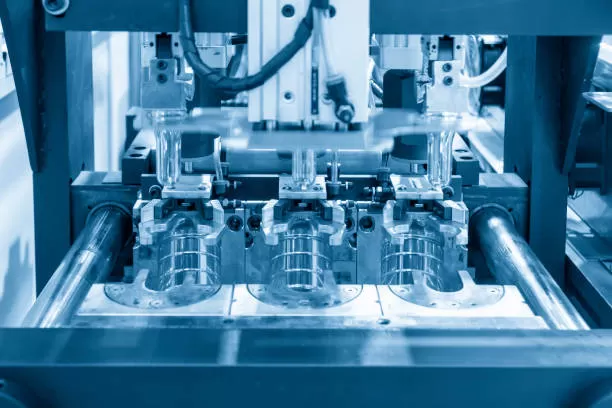

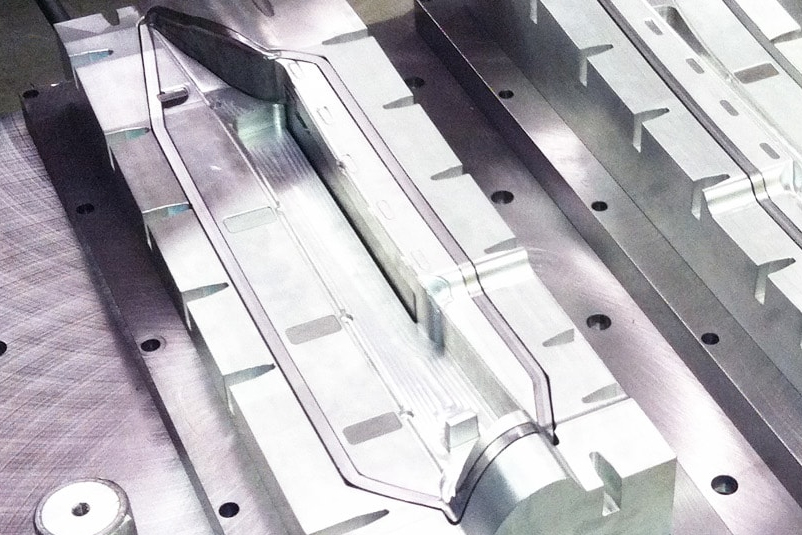

Plastic Molds

Rubber Molds

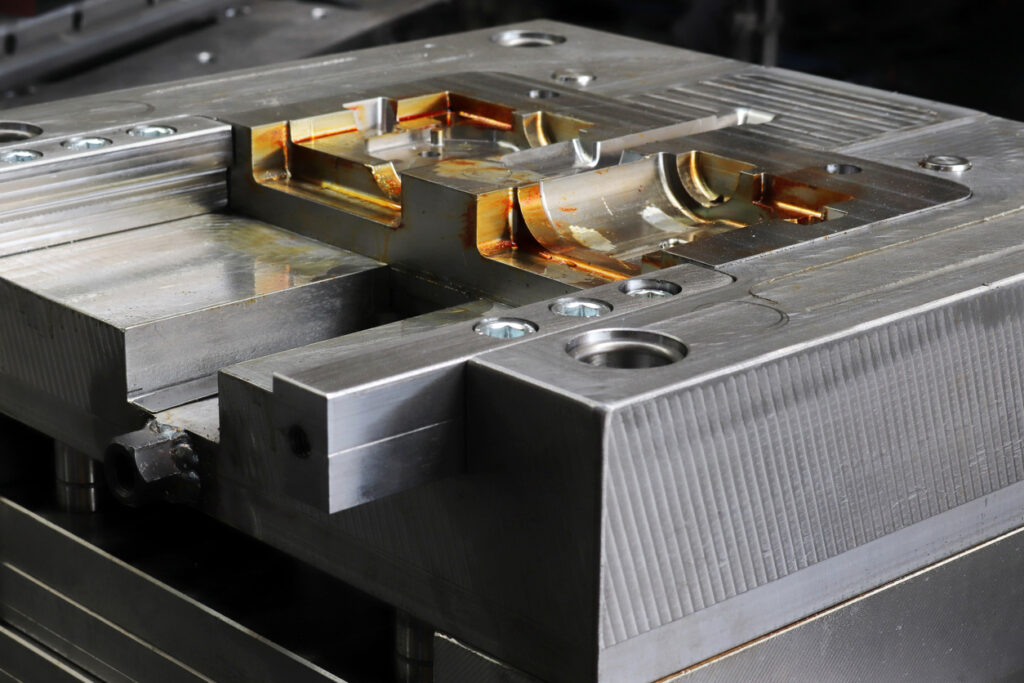

Stamping

Die Cast Dies

Pins

Unique Characteristics

- Despite hardness of nominal 45 HRC, this new steel is easy to machine.

- Particularly suitable for manufacturing plastic molds because it can be polished and etched with very good results.

- Great for guide rails, bending tools, etc. when high stability materials are required.

- Capable of A2 Polish.

Product Brochure

Recommended Reading

Presentations on:

- Moulds and Dies

- Cold Forming Applications

- Diecasting Applications

- Engineering Applications

- Plastics Applications

Toolox 44 Application:

Toolox 44 Tool Testing:

Articles on:

Specifications

| Hardness | Hardness range 41 – 47 HRC | |

| Impact toughness |

Test temperature ºF 68

Impact energy, Charpy-V-test for plate, direction; Guaranteed minimum Ft. lbs. 14 |

|

| Milling | At cutting speed of 140m/mm, feed 0.15mm and 10min effective machining time using Sandvik Coromil 200 and inserts GC 1025, we guarantee maximum edge wear of 0.3mm | |

| Etching | Toolox 44 fulfills the etching requirements of NADCA 207-2003 | |

| Dimensions | Toolox 44 is supplied as plate in thickness between .200″ – 5 1/8″ | |

| Heat treatment | Toolox 44 is not intended for further heat treatments. If Toolox 44 is heated above 590º C, no guarantees for the properties of the steel can be given. | |

| Nitriding/coating | Below temperature <590º C / 1094 ºF | |

Usages

Toolox 44 is a new quenched and tempered steel designed to have high impact resistance and low residual stresses and therefore good dimensional stability. Despite a hardness of 45 HRC, the new steel is easily machined. Toolox 44 is particularly suitable for manufacturing plastic molds because it can be polished and etched with very good results. Fields of application: plastic molds, rubber molds, wear components and machine components, such as guide rails, bending tools, etc., where stability materials are required.

Toolox 44 is a new quenched and tempered steel designed to have high impact resistance and low residual stresses and therefore good dimensional stability. Despite a hardness of 45 HRC, the new steel is easily machined. Toolox 44 is particularly suitable for manufacturing plastic molds because it can be polished and etched with very good results. Fields of application: plastic molds, rubber molds, wear components and machine components, such as guide rails, bending tools, etc., where stability materials are required.

Technical Information (Typical Values)

Machining

Toolox 44 can be machined on conventional machines. It is important that sharp tools are used with a positive cutting angle and that vibration is avoided. Use the following recommendations as guidelines and the starting point for your own evaluation of best practice.

Recommended preheat temperature when gas cutting and welding Minimum 250º C Recommended stress

Recommended preheat temperature when gas cutting and welding Minimum 250º C Recommended stress

relief annealing (after slow cooling to room temperature ) after gas cutting and welding 580º C

Video

Presentations on:

- Moulds and Dies

- Cold Forming Applications

- Diecasting Applications

- Engineering Applications

- Plastics Applications

Toolox 44 Application:

Toolox 44 Tool Testing:

Articles on:

- Quality Steel for Advanced Gear Racks

- Cutting Tooling Costs

- Case Study: Alternative to Conventional Steel for Mould Inserts Extends Tool Life, Cuts Costs

| Hardness | Hardness range 41 – 47 HRC | |

| Impact toughness |

Test temperature ºF 68

Impact energy, Charpy-V-test for plate, direction; Guaranteed minimum Ft. lbs. 14 |

|

| Milling | At cutting speed of 140m/mm, feed 0.15mm and 10min effective machining time using Sandvik Coromil 200 and inserts GC 1025, we guarantee maximum edge wear of 0.3mm | |

| Etching | Toolox 44 fulfills the etching requirements of NADCA 207-2003 | |

| Dimensions | Toolox 44 is supplied as plate in thickness between .200″ – 5 1/8″ | |

| Heat treatment | Toolox 44 is not intended for further heat treatments. If Toolox 44 is heated above 590º C, no guarantees for the properties of the steel can be given. | |

| Nitriding/coating | Below temperature <590º C / 1094 ºF | |

Toolox 44 is a new quenched and tempered steel designed to have high impact resistance and low residual stresses and therefore good dimensional stability. Despite a hardness of 45 HRC, the new steel is easily machined. Toolox 44 is particularly suitable for manufacturing plastic molds because it can be polished and etched with very good results. Fields of application: plastic molds, rubber molds, wear components and machine components, such as guide rails, bending tools, etc., where stability materials are required.

Toolox 44 is a new quenched and tempered steel designed to have high impact resistance and low residual stresses and therefore good dimensional stability. Despite a hardness of 45 HRC, the new steel is easily machined. Toolox 44 is particularly suitable for manufacturing plastic molds because it can be polished and etched with very good results. Fields of application: plastic molds, rubber molds, wear components and machine components, such as guide rails, bending tools, etc., where stability materials are required.

Technical Information (Typical Values)

Toolox 44 can be machined on conventional machines. It is important that sharp tools are used with a positive cutting angle and that vibration is avoided. Use the following recommendations as guidelines and the starting point for your own evaluation of best practice.

Recommended preheat temperature when gas cutting and welding Minimum 250º C Recommended stress

Recommended preheat temperature when gas cutting and welding Minimum 250º C Recommended stress

relief annealing (after slow cooling to room temperature ) after gas cutting and welding 580º C

https://youtube.com/watch?v=M88xzHkA7iA%3Fcontrols%3D1%26rel%3D0%26playsinline%3D0%26modestbranding%3D0%26enablejsapi%3D1%26origin%3Dhttps%253A%252F%252Fimsteel.com%26autoplay%3D1