Description

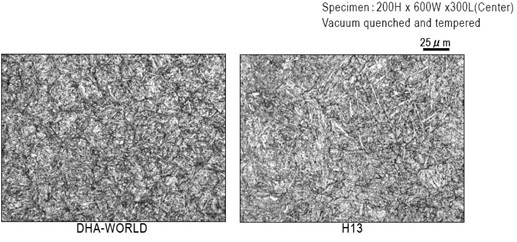

Improved H13 applicable for a wide variety of uses High toughness even in large dies due to higher hardenability than that of H13

Applications include:

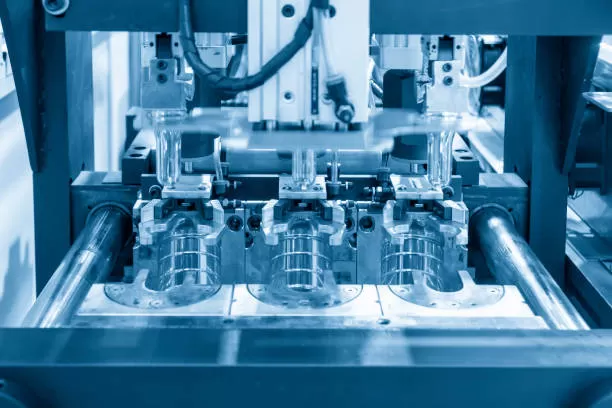

Die Casting Molds

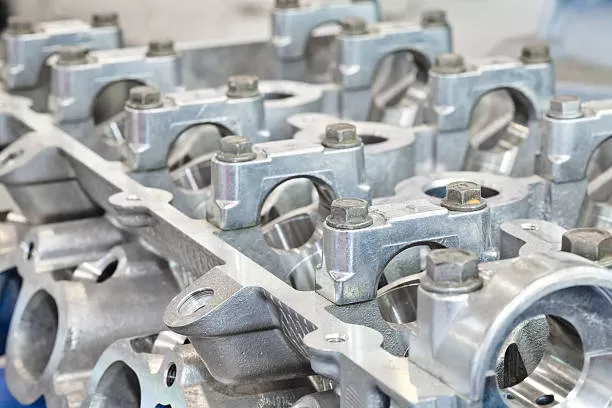

Die Casting Parts

Hot Extrusion Dies

Hot Shear Blades

Hot Forging Dies

Unique Characteristics

- 38-42 HRc hardness.

- Through hardened for exceptional dimensional stability.

- Cuts mold making costs by reducing man hours required for machining.

- Classified as a “free-machining” steel.

- Ideal for complex, precision molds and parts susceptible to distortion and/or deformation without needing additional heat-treating.

- Ideal for Ion-nitriding.

Product Brochure

PHYSICAL PROPERTIES

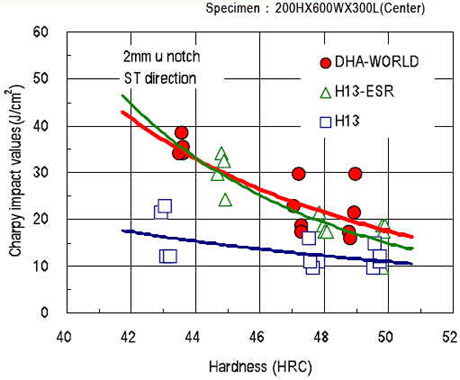

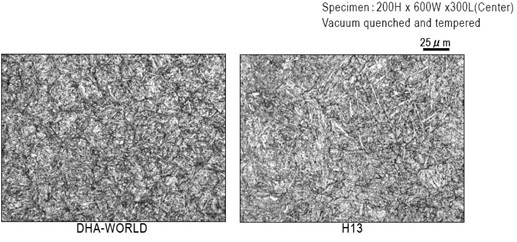

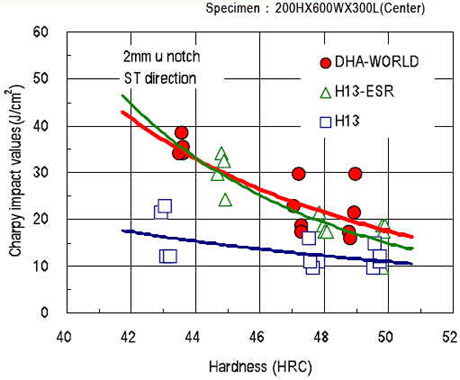

Toughness

CCT Curves

Heat Checking Resistance

Dimensional Change

Softening Resistance

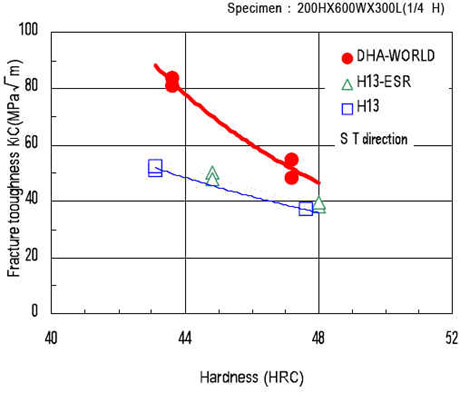

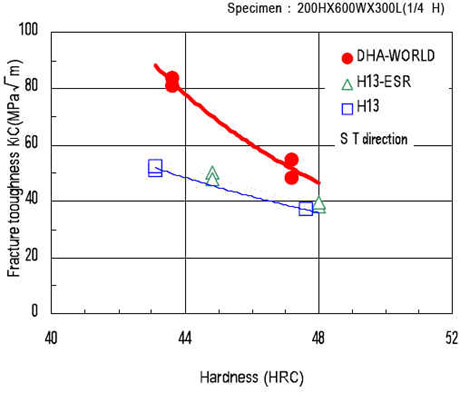

Fracture Toughness

Quenching Rate vs. Toughness

AI Erosion Resistance

Nitriding Characteristics

Thermal

![]()

Thermal Conductivity

![]()

Specific Heat

Specific Weight

Machinability

Recommended Reading

Toughness

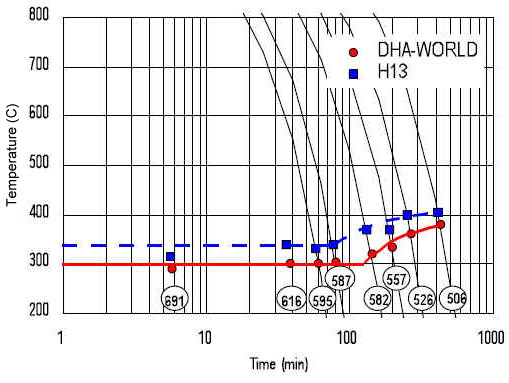

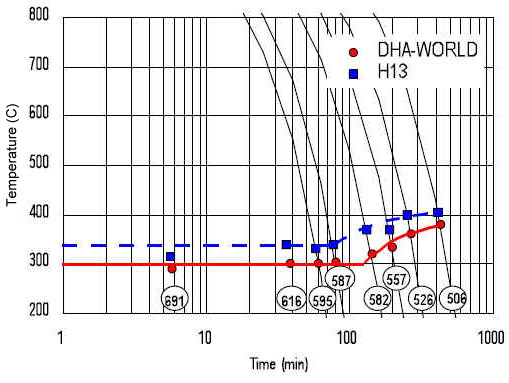

CCT Curves

Heat Checking Resistance

Dimensional Change

Softening Resistance

Fracture Toughness

Quenching Rate vs. Toughness

AI Erosion Resistance

Nitriding Characteristics

Thermal

![]()

Thermal Conductivity

![]()

Specific Heat

Specific Weight